| MASS AIR FLOW | -18% |

| PRESSURE DROP | CONSTANT |

| SHAPE CONSTRAINTS | OK |

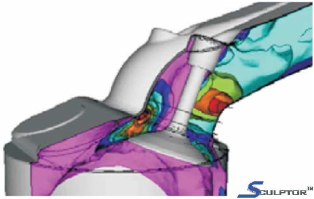

In internal combustion engines, the intake port shape is crucial to control the air flow entering the cylinder, and hence emissions and performances. Usually, it has to deliver an adequate mass flow to the valve passage, while containing the pressure losses. Intake port geometry is also exposed to tight shape constraints, since it's located in a compact and critical zone of the engine.

The geometry of an existing intake port had to be changed in order to achieve performance and efficiency improvements without expensive engine layout changes. The main goal was to increase the air mass flow in the intake port, while respecting the prescribed pressure loss. Also, any geometry variation had to respect precise shape constraints. Finally, design cost and time had to be minimized.

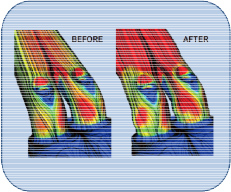

Sculptor™, coupled with a CFD code, enabled the users to find an improved and feasible inlet port geometry in just one week, while with only CFD it would have taken several weeks or months. With subtle shape modifications, a 1.9% increase of the mass flow rate was achieved without any compromise on the pressure drop.

The new configuration respects all the shape constraints and represents a cheap manufacturing solution. Sculptor™ avoided time consuming operations on the Computer Aided Design (CAD) model and on the computational grid, since its morphing took place on the CFD model directly.

Sculptor™, coupled with a CFD code, enabled the users to find an improved and feasible inlet port geometry in just one week, while with only CFD it would have taken several weeks or months. With subtle shape modifications, a 1.9% increase of the mass flow rate was achieved without any compromise on the pressure drop.

The new configuration respects all the shape constraints and represents a cheap manufacturing solution. Sculptor™ avoided time consuming operations on the Computer Aided Design (CAD) model and on the computational grid, since its morphing took place on the CFD model directly.

The original engine intake port geometry had to be refined while respecting constraints on some cross-sections: a maximum of 15% of variations was allowed for the area. The mass air flow

through the port had to be increased, without affecting the pressure drop.

The original engine intake port geometry had to be refined while respecting constraints on some cross-sections: a maximum of 15% of variations was allowed for the area. The mass air flow

through the port had to be increased, without affecting the pressure drop.

Sculptor™'s morphing technology was applied over a Computational Fluid Dynamic (CFD) model of the inlet port

system, to define its optimal shape. The original mesh was imported and prepared for morphing. Eleven parameters were

defined and set in a way that took into account the constraints mentioned above.

Sculptor™'s morphing technology was applied over a Computational Fluid Dynamic (CFD) model of the inlet port

system, to define its optimal shape. The original mesh was imported and prepared for morphing. Eleven parameters were

defined and set in a way that took into account the constraints mentioned above.

Using Arbitrary Shape Deformation (ASD) volumes, one hundred and twenty three configurations were instantly generated by

changing the parameter values, without the need of re-creating the mesh. Such new configurations were then submitted to a CFD

analysis code and evaluated. Finally, the best configuration was selected.

Using Arbitrary Shape Deformation (ASD) volumes, one hundred and twenty three configurations were instantly generated by

changing the parameter values, without the need of re-creating the mesh. Such new configurations were then submitted to a CFD

analysis code and evaluated. Finally, the best configuration was selected.

Sculptor™, coupled with a CFD code, allowed finding the optimal engine inlet port geometry in just one week. With only CFD code, it would have taken several weeks or months. The total costs were 86% less with respect to the traditional design method. In the table below the breakdown of the costs is presentd, based on the estimation of man-hour cost of ($90 / hour), CFD code hourly cost ($10.75 / hour) and a Sculptor™ hourly cost of ($10.75 / hour). 80 designs needed to be evaluated.

Sculptor™ is developed by Optimal Solutions Software LLC, based in Idaho, USA. The Optimal Solutions Management team is comprised of some of the most experienced CFD-based shape optimization personnel in the business. Since 1990, the re-search team has expended thousands of man-hours in design-ing and refining the Sculptor™ software program to its pre-sent form. Through the development of the Sculptor™ world-class, patent-pending product family, Optimal Solutions has been able to effectively address the current barriers that pre-vent the efficient use of digital simulation.

The team at Optimal Solutions Software is happy to perform a no-cost initial design assessment on your model. Contact Us today and we will obtain the deformation constraints from you and demonstrate how Sculptor can save you time and money. We have worked with all sizes of companies and have NDA's in place with most major firms and can quickly get to work on your model.

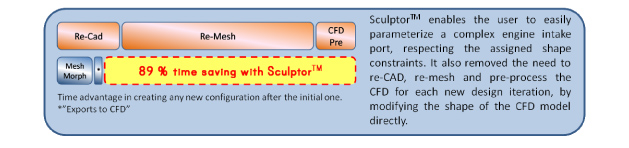

Sculptor enabled optimization of the HVAC design resulting in significantly improved performance with an 89 % time savings and a 90% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the HVAC design resulting in significantly improved performance with an 89 % time savings and a 90% cost savings to the customer as compared to other methods.

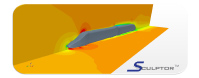

Sculptor enabled an 8% increase of overall lift/drag ratio, a 90 % time savings, and a 91% cost savings to the customer as compared to other methods.

Sculptor enabled an 8% increase of overall lift/drag ratio, a 90 % time savings, and a 91% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the aerodynamic design with a 90 % time savings and as compared to other methods.

Sculptor enabled optimization of the aerodynamic design with a 90 % time savings and as compared to other methods.

Sculptor enabled the customer to match "hot" turbine blade models to "cold" shape with a 62 % time savings and a 62% cost savings to the customer when compared to other methods.

Sculptor enabled the customer to match "hot" turbine blade models to "cold" shape with a 62 % time savings and a 62% cost savings to the customer when compared to other methods.

Sculptor enabled optimization of the high speed train design resulting in reduced drag, reduced emissions and improved efficiencies with an 85 % time savings and a 92% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the high speed train design resulting in reduced drag, reduced emissions and improved efficiencies with an 85 % time savings and a 92% cost savings to the customer as compared to other methods.

Sculptor enabled evaluation of 124 design variants with an 86 % time savings and an 86% cost savings to the customer when compared to other methods.

Sculptor enabled evaluation of 124 design variants with an 86 % time savings and an 86% cost savings to the customer when compared to other methods.