| AERODYNAMIC EFFICIENCY | +8% |

| TURBINE NACELLE | UNCHANGED |

| SHAPE CONSTRAINTS | MAINTED |

Commercial airplanes are encountering increasing efficiency requirements and emissions restrictions, hence major efforts are ongoing to innovate their aerodynamic design. For instance, the wing shape contributes substantially to the overall aerodynamic performance of the airplane. Typically 3D wing design should guarantee an improved ratio between aerodynamic lift force and drag force with respect to reference designs. The turbin engine nacelle and fuselage shapes might be already in a frozen design state and therefore become the constraints.

The 3D geometry of an existing commercial airplane wing had to be re-shaped in order to achieve efficiency improvements. The main goal was to increase the lift/drag ratio at subsonic cruise conditions, without modifying fuselage and turbine engine nacelle shapes. All this was achieved through a new design process that minimizes costs, time and access to CAD resources and resulting in an improved CAD model.

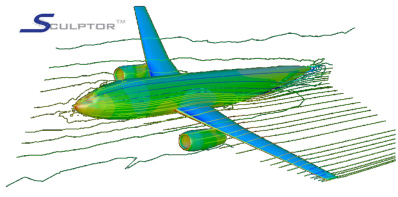

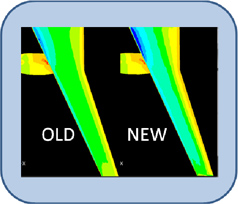

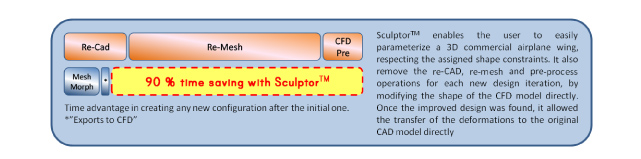

Sculptor™, coupled with a CFD code, allowed finding an improved 3D wing shape in just a few days, while with only CFD it would have taken several weeks. With subtle shape modifications, a sound 8% increase of overall lift/drag ratio was achieved—without affecting the fuselage and turbine nacelle shapes. Sculptor™ avoided time consuming operations on Computer Aided Design (CAD) model and on the computational grid, since its morphing took place over the CFD model directly. Finally, the optimized airplane shape was applied to the original CAD model.

Sculptor™, coupled with a CFD code, allowed finding an improved 3D wing shape in just a few days, while with only CFD it would have taken several weeks. With subtle shape modifications, a sound 8% increase of overall lift/drag ratio was achieved—without affecting the fuselage and turbine nacelle shapes. Sculptor™ avoided time consuming operations on Computer Aided Design (CAD) model and on the computational grid, since its morphing took place over the CFD model directly. Finally, the optimized airplane shape was applied to the original CAD model.

A reference 3D wing geometry had to be refined with respect to a defined industry standard design. Fuselage and nacelle shapes had to be left untouched. The airplane aerodynamic lift/drag ratio had to be maximized at subsonic cruise conditions.

A reference 3D wing geometry had to be refined with respect to a defined industry standard design. Fuselage and nacelle shapes had to be left untouched. The airplane aerodynamic lift/drag ratio had to be maximized at subsonic cruise conditions.

Sculptor™'s morphing technology was applied over a Computational Fluid Dynamic (CFD) model of the commercial airplane, to define the optimal 3D shape of its wing. The original mesh was imported and the wing was prepared for morphing while respecting the nacelle and fuselage shape constraints. Ten parameters and the objective function were defined, Sculptor was then connected to the CFD solver

Sculptor™'s morphing technology was applied over a Computational Fluid Dynamic (CFD) model of the commercial airplane, to define the optimal 3D shape of its wing. The original mesh was imported and the wing was prepared for morphing while respecting the nacelle and fuselage shape constraints. Ten parameters and the objective function were defined, Sculptor was then connected to the CFD solver

Using Arbitrary Shape Deformation (ASD) volumes, fifty configurations were instantly generated by Sculptor by changing the parameter values — without the need of re-creating the mesh. New configurations were then automatically submitted to a CFD analysis code and evaluated. Finally, the best configuration was selected and its shape was applied to the original CAD model

Using Arbitrary Shape Deformation (ASD) volumes, fifty configurations were instantly generated by Sculptor by changing the parameter values — without the need of re-creating the mesh. New configurations were then automatically submitted to a CFD analysis code and evaluated. Finally, the best configuration was selected and its shape was applied to the original CAD model

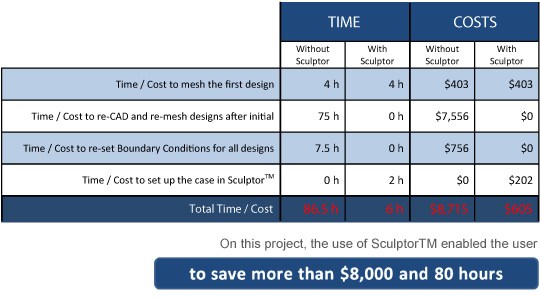

Sculptor™, coupled with a CFD code, allowed finding the optimal engine inlet port geometry in just one week. With only CFD code, it would have taken several weeks or months. The total costs were 86% less with respect to the traditional design method. In the table below the breakdown of the costs is presentd, based on the estimation of man-hour cost of ($90 / hour), CFD code hourly cost ($10.75 / hour) and a Sculptor™ hourly cost of ($10.75 / hour). 80 designs needed to be evaluated.

Sculptor™ is developed by Optimal Solutions Software LLC, based in Idaho, USA. The Optimal Solutions Management team is comprised of some of the most experienced CFD-based shape optimization personnel in the business. Since 1990, the re-search team has expended thousands of man-hours in design-ing and refining the Sculptor™ software program to its pre-sent form. Through the development of the Sculptor™ world-class, patent-pending product family, Optimal Solutions has been able to effectively address the current barriers that pre-vent the efficient use of digital simulation.

The team at Optimal Solutions Software is happy to perform a no-cost initial design assessment on your model. Contact us today and we will obtain the deformation constraints from you and demonstrate how Sculptor can save you time and money. We have worked with all sizes of companies and have NDA's in place with most major firms and can quickly get to work on your model.

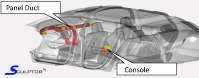

Sculptor enabled optimization of the HVAC design resulting in significantly improved performance with an 89 % time savings and a 90% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the HVAC design resulting in significantly improved performance with an 89 % time savings and a 90% cost savings to the customer as compared to other methods.

Sculptor enabled an 8% increase of overall lift/drag ratio, a 90 % time savings, and a 91% cost savings to the customer as compared to other methods.

Sculptor enabled an 8% increase of overall lift/drag ratio, a 90 % time savings, and a 91% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the aerodynamic design with a 90 % time savings and as compared to other methods.

Sculptor enabled optimization of the aerodynamic design with a 90 % time savings and as compared to other methods.

Sculptor enabled the customer to match "hot" turbine blade models to "cold" shape with a 62 % time savings and a 62% cost savings to the customer when compared to other methods.

Sculptor enabled the customer to match "hot" turbine blade models to "cold" shape with a 62 % time savings and a 62% cost savings to the customer when compared to other methods.

Sculptor enabled optimization of the high speed train design resulting in reduced drag, reduced emissions and improved efficiencies with an 85 % time savings and a 92% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the high speed train design resulting in reduced drag, reduced emissions and improved efficiencies with an 85 % time savings and a 92% cost savings to the customer as compared to other methods.

Sculptor enabled evaluation of 124 design variants with an 86 % time savings and an 86% cost savings to the customer when compared to other methods.

Sculptor enabled evaluation of 124 design variants with an 86 % time savings and an 86% cost savings to the customer when compared to other methods.