| DRAG | -5.88% |

| DESIGNS | 100 |

| TIME | 15 MIN |

The high speed train market in recently industrialized countries is one of the most hotly contested markets in the world. Even the smallest advantage is exploited for higher sales. Fuel consumption is a significant factor now playing a role in design, sales, and maintenance of these vehicles. With that in mind a customer was looking to maximize efficiency, reduce emissions, and decrease design time.

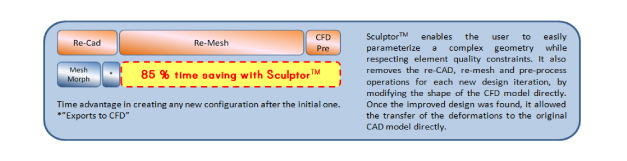

A more efficient approach needed to be taken in order to maximize the number of designs that could be tested. Sculptor was just the tool for the job. By specifying key design parameters hundreds of designs could be generated in matter of minutes, the previous process took months.

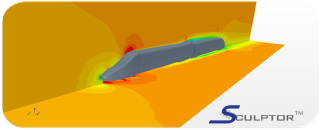

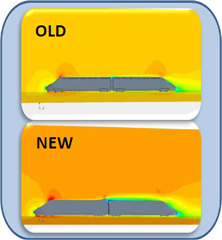

Sculptor™, coupled with modeFrontier a Multi-Objective Optimization code from ESTECO, and starCCM+ a CFD analysis tool from CD-Adapco , allowed the customer to find an aerodynamic design that decreased the drag by more than 5%, increased aerodynamic efficiency and ultimately increased fuel efficiency. All of the design changes were completed in less than one hour, while with wind tunnels or only CFD codes it would have taken several weeks or months. Moreover, Sculptor™ avoided time consuming operations on the Computer Aided Design (CAD) vehicle model and on the computational grid, since its morphing takes place over the CFD model directly.

Sculptor™, coupled with modeFrontier a Multi-Objective Optimization code from ESTECO, and starCCM+ a CFD analysis tool from CD-Adapco , allowed the customer to find an aerodynamic design that decreased the drag by more than 5%, increased aerodynamic efficiency and ultimately increased fuel efficiency. All of the design changes were completed in less than one hour, while with wind tunnels or only CFD codes it would have taken several weeks or months. Moreover, Sculptor™ avoided time consuming operations on the Computer Aided Design (CAD) vehicle model and on the computational grid, since its morphing takes place over the CFD model directly.

Using Arbitrary Shape Deformation (ASD) volumes, different configurations were instantly tested, without the need of re-creating the mesh. 100 different geometries were tested and one was found that reduced the drag by more than 5%.

Using Arbitrary Shape Deformation (ASD) volumes, different configurations were instantly tested, without the need of re-creating the mesh. 100 different geometries were tested and one was found that reduced the drag by more than 5%.

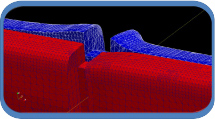

5 Control groups were defined with individual deformation vectors based on manufacturing constraints and realistic aerodynamic estimations. These groups were used as design variables in the setup of the optimization.

5 Control groups were defined with individual deformation vectors based on manufacturing constraints and realistic aerodynamic estimations. These groups were used as design variables in the setup of the optimization.

Sculptor™'s morphing technology combined with the 5 control groups was applied over the Computational Fluid Dynamic (CFD) model of the train. Using the optimizer to determine which configurations should be tested, Sculptor took 15 minutes to generate 36 designs. These de-signs were then automatically sent to the CFD code and analyzed.

Sculptor™'s morphing technology combined with the 5 control groups was applied over the Computational Fluid Dynamic (CFD) model of the train. Using the optimizer to determine which configurations should be tested, Sculptor took 15 minutes to generate 36 designs. These de-signs were then automatically sent to the CFD code and analyzed.

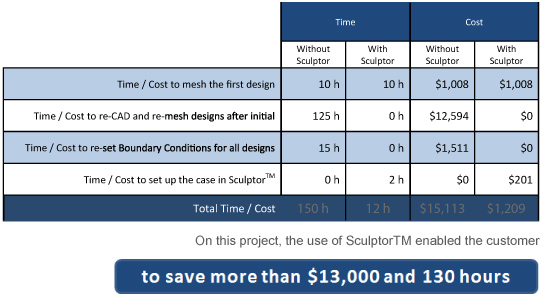

Sculptor™, coupled with a starCCM+, allowed finding the optimal aerodynamic design in a few days, while CFD only would have taken several weeks. The total costs were 79% less with respect to the traditional design method. In the table below the breakdown of the costs is presented, based on the estimation of man-hour cost of ($90 / hour), CFD code hourly cost ($10.75 / hour) and a Sculptor™ hourly cost of ($10.75 / hour). 80 designs needed to be evaluated.

Sculptor™ is developed by Optimal Solutions Software LLC, based in Idaho, USA. The Optimal Solutions Management team is comprised of some of the most experienced CFD-based shape optimization personnel in the business. Since 1990, the re-search team has expended thousands of man-hours in design-ing and refining the Sculptor™ software program to its pre-sent form. Through the development of the Sculptor™ world-class, patent-pending product family, Optimal Solutions has been able to effectively address the current barriers that pre-vent the efficient use of digital simulation.

The team at Optimal Solutions Software is happy to perform a no-cost initial design assessment on your model. Contact us today and we will obtain the deformation constraints from you and demonstrate how Sculptor can save you time and money. We have worked with all sizes of companies and have NDA's in place with most major firms and can quickly get to work on your model.

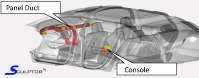

Sculptor enabled optimization of the HVAC design resulting in significantly improved performance with an 89 % time savings and a 90% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the HVAC design resulting in significantly improved performance with an 89 % time savings and a 90% cost savings to the customer as compared to other methods.

Sculptor enabled an 8% increase of overall lift/drag ratio, a 90 % time savings, and a 91% cost savings to the customer as compared to other methods.

Sculptor enabled an 8% increase of overall lift/drag ratio, a 90 % time savings, and a 91% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the aerodynamic design with a 90 % time savings and as compared to other methods.

Sculptor enabled optimization of the aerodynamic design with a 90 % time savings and as compared to other methods.

Sculptor enabled the customer to match "hot" turbine blade models to "cold" shape with a 62 % time savings and a 62% cost savings to the customer when compared to other methods.

Sculptor enabled the customer to match "hot" turbine blade models to "cold" shape with a 62 % time savings and a 62% cost savings to the customer when compared to other methods.

Sculptor enabled optimization of the high speed train design resulting in reduced drag, reduced emissions and improved efficiencies with an 85 % time savings and a 92% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the high speed train design resulting in reduced drag, reduced emissions and improved efficiencies with an 85 % time savings and a 92% cost savings to the customer as compared to other methods.

Sculptor enabled evaluation of 124 design variants with an 86 % time savings and an 86% cost savings to the customer when compared to other methods.

Sculptor enabled evaluation of 124 design variants with an 86 % time savings and an 86% cost savings to the customer when compared to other methods.