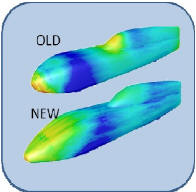

| DRAG | -18% |

| SPEED | +47% |

| DOWN FORCE | +400% |

In land speed racing, a streamliner is a long, slender, high-speed vehicle with enclosed wheels. Three times a year vehicles of this kind participate in races at the Bonneville salt flats in Utah, USA. This particular Streamliner is an all electric streamliner weighing less than 500 kg that was developed by Brigham Young University in Provo, Utah, USA. The University is attempting to break a land speed record for light electric vehicles.

A new streamliner design needed to be invented, to improve the current top speed record in its category—219 km/h. A very efficient aerodynamic design was needed to reach this goal, while safety requirements had to be respected. Besides that, design cost and time had to be minimized.

Sculptor™, coupled with a Multi-Objective Optimization code, allowed finding the optimal vehicle aerodynamic design in less than one week, while with wind tunnels or only CFD codes it would have taken several weeks or months. The shape was substantially changed, and an estimated 47% speed increase was reached. At the same time, safety was increased by 400%. This approach

allowed to completely define the designs in one week, without the need of any preliminary wind tunnel tests. Moreover, Sculptor™ avoided time consuming operations on the Computer Aided Design (CAD) vehicle

model and on the computational grid, since its

morphing takes place over the CFD model directly.

Sculptor™, coupled with a Multi-Objective Optimization code, allowed finding the optimal vehicle aerodynamic design in less than one week, while with wind tunnels or only CFD codes it would have taken several weeks or months. The shape was substantially changed, and an estimated 47% speed increase was reached. At the same time, safety was increased by 400%. This approach

allowed to completely define the designs in one week, without the need of any preliminary wind tunnel tests. Moreover, Sculptor™ avoided time consuming operations on the Computer Aided Design (CAD) vehicle

model and on the computational grid, since its

morphing takes place over the CFD model directly.

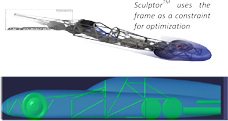

The surface of the streamliner needed to be shaped over a defined frame. The front end and the under-carriage had to be designed so that its aerodynamic design would generate low drag

force with the needed down force. The first was beneficial in achieving the top-speed record, the second was necessary to keep the vehicle down

to the ground and allow the necessary safety

and traction.

The surface of the streamliner needed to be shaped over a defined frame. The front end and the under-carriage had to be designed so that its aerodynamic design would generate low drag

force with the needed down force. The first was beneficial in achieving the top-speed record, the second was necessary to keep the vehicle down

to the ground and allow the necessary safety

and traction.

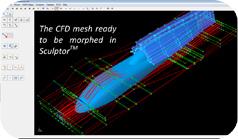

Sculptor™'s morphing technology was applied over a Computational Fluid Dynamic (CFD) model of the vehicle, to

define its optimal external skin surface. The original mesh was read into Sculptor™, and the model was prepared

for morphing.

Sculptor™'s morphing technology was applied over a Computational Fluid Dynamic (CFD) model of the vehicle, to

define its optimal external skin surface. The original mesh was read into Sculptor™, and the model was prepared

for morphing.

Using Arbitrary Shape Deformation (ASD) volumes, different configurations were instantly tested, without the need of re-creating the mesh. By moving the control points, new configurations were created immediately and then submitted to CFD. Finally, the configuration giving the best results was chosen.

Using Arbitrary Shape Deformation (ASD) volumes, different configurations were instantly tested, without the need of re-creating the mesh. By moving the control points, new configurations were created immediately and then submitted to CFD. Finally, the configuration giving the best results was chosen.

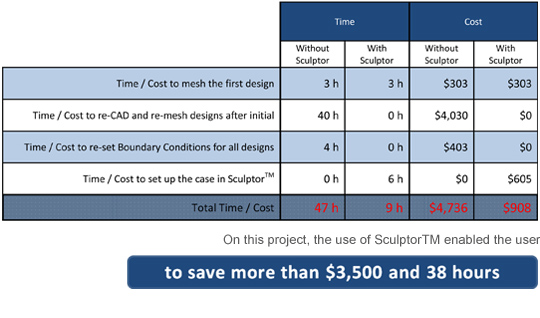

Sculptor™, coupled with a CFD code, allowed finding the optimal aerodynamic design in a few days, while CFD only would have taken several weeks. The total costs were 81% less with respect to the traditional design method. In the table below the breakdown of the costs is presentd, based on the estimation of man-hour cost of ($90 / hour), CFD code hourly cost ($10.75 / hour) and a Sculptor™ hourly cost of ($10.75 / hour). 80 designs needed to be evaluated.

Sculptor™ is developed by Optimal Solutions Software LLC, based in Idaho, USA. The Optimal Solutions Management team is comprised of some of the most experienced CFD-based shape optimization personnel in the business. Since 1990, the re-search team has expended thousands of man-hours in design-ing and refining the Sculptor™ software program to its pre-sent form. Through the development of the Sculptor™ world-class, patent-pending product family, Optimal Solutions has been able to effectively address the current barriers that pre-vent the efficient use of digital simulation.

The team at Optimal Solutions Software is happy to perform a no-cost initial design assessment on your model. Contact us today and we will obtain the deformation constraints from you and demonstrate how Sculptor can save you time and money. We have worked with all sizes of companies and have NDA's in place with most major firms and can quickly get to work on your model.

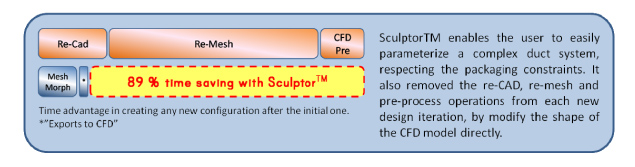

Sculptor enabled optimization of the HVAC design resulting in significantly improved performance with an 89 % time savings and a 90% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the HVAC design resulting in significantly improved performance with an 89 % time savings and a 90% cost savings to the customer as compared to other methods.

Sculptor enabled an 8% increase of overall lift/drag ratio, a 90 % time savings, and a 91% cost savings to the customer as compared to other methods.

Sculptor enabled an 8% increase of overall lift/drag ratio, a 90 % time savings, and a 91% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the aerodynamic design with a 90 % time savings and as compared to other methods.

Sculptor enabled optimization of the aerodynamic design with a 90 % time savings and as compared to other methods.

Sculptor enabled the customer to match "hot" turbine blade models to "cold" shape with a 62 % time savings and a 62% cost savings to the customer when compared to other methods.

Sculptor enabled the customer to match "hot" turbine blade models to "cold" shape with a 62 % time savings and a 62% cost savings to the customer when compared to other methods.

Sculptor enabled optimization of the high speed train design resulting in reduced drag, reduced emissions and improved efficiencies with an 85 % time savings and a 92% cost savings to the customer as compared to other methods.

Sculptor enabled optimization of the high speed train design resulting in reduced drag, reduced emissions and improved efficiencies with an 85 % time savings and a 92% cost savings to the customer as compared to other methods.

Sculptor enabled evaluation of 124 design variants with an 86 % time savings and an 86% cost savings to the customer when compared to other methods.

Sculptor enabled evaluation of 124 design variants with an 86 % time savings and an 86% cost savings to the customer when compared to other methods.